|

|

|

|

|

|

|

|

|

|

|

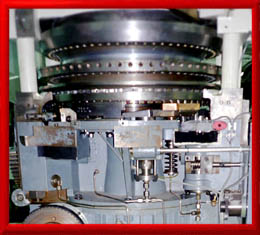

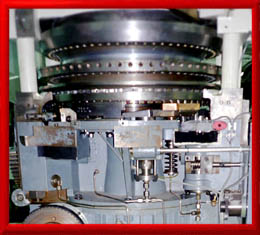

The Killian RX-67 was a tablet press that was purchased at a liquidation auction by Union Standard. The electrics on this machine were very badly mangled, which you will see in the slide show. Fortunately Union got the original book with the schematics when they bought the machine. Using this data I was able to restore it to like new condition again for a customer who bought it. What made this machine unique is that it had a force feed back system that used a strain gauge to monitor the back pressure of the compaction dies as they were being descending into their matching cavities (holes) to compact the powder. The output signal would be used to adjust the hydraulic pressure behind the compaction wheels to make sure a constant compression force was being applied to make each tablet. I had to buy all new strain gauge amplifiers and controls from Omega, but I got the whole thing working again.

Now let me explain to you how tablets are made. Tablets represent one of the most common forms for unitizing powdered ingredients into a single compact product. This is by far the most popular method used to make medicines and vitamins. These machines cause the powder to get compacted together by subjecting it to extreme pressure and some heat as well. The way it does this is by using a set of high-speed roller compacted die sets, usually 2 for each tablet, one upper die and one lower die. Here is how it works:

At the heart of these machines is giant rotary table called a die wheel. On the perimeter of this table are a series of holes bored around the circumference. Their diameter is equal to the diameter of one tablet and their axis is parallel to the axis of the table disk itself. Positioned above and below each hold is a pair of punch die sets. There is an upper die and a lower die. These are mounted in their own concentric carrier wheels that are on the same axis as the rotary table. The pockets in the carrier wheels hold each die pair inline with its own tablet hole on the rotary table at all times. Each die has a large diameter head on the far end that rides in a circular guide track.

When this machine runs the rotary table and die sets are rotating around constantly at high speed. At one point in the 360-degree cycle of rotation of the table, the upper dies are pulled up and all the way out of their matching tablet holes. A powder feed mechanism doses each hole as it is whizzing by with the correct amount of powder to be compacted. Right after that the track descends the die back into the upper hole. For a split second after that both the upper and lower die sets are passed between a pair of roller compaction wheels, which forces the upper and lower dies together and crushes the powder in between them into a tablet. The sudden heat of the friction from compressing the powder together causes a binding agent in the powder mix to temporarily melt and bind the ingredients together as it cools. As the table turns further the lower die is withdrawn from the hole by the lower guide track. Then the upper guide track descends the upper die all the way into the tablet hole, which then pushes the finished tablet out from the bottom of the rotary table hole towards an ejection collection accumulation point located under the rotary table. After that the guide tracks reset the dies into position to get changed with powder once again. This cycle takes place at high speeds and hundreds of tablets are produced per minute.

I have worked on many different versions of these machines, from the single motor type with no sensors, to full-blown computer controlled machines. I have even done some total rebuilds on the electrics of these machines. You can see that in the slide shows.

Because of the strain gauge system on the Killian I had to plow into a lot of books to do some research to figure out what I should do, but that is what nmakes these challenges fun for me, because I keep on learning more as I go along.