|

|

|

|

|

|

|

|

|

|

|

Whether Horizontal or Vertical the reason it is called Form Fill and Seal is because part of the bag or wrapper is being formed off a continuously fed roll of wrapping material as the product is added to the bag. As the product is added to the bag the rest of the bag is literally formed around the product and sealed. The seal not only closes the end of the newly formed bag, it also creates the leading edge of the next bag too, and the process begins again. Hence the term 1) FORM 2) Fill 3) SEAL, and that is where the similarity ends.

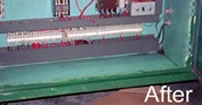

Examples of the horizontal process of Form Fill Seal are all the wrapped candy bars you see out there today. These are fragile and their appearance can be damaged from vertical dropping. Instead the candy bars usually emerge from a conveyor line and get placed onto the pusher chain or infeed section of the HFFSM. The chain has vertical tabs at regular intervals to control the speed and spacing between candy bars, which is important because without that timing the candy bar could get crushed by a parallel set of rotating heat seal jaws that make the seal between each bag. The long seam in the back of the wrapper, which is many times called the fin seal, is heat sealed between the two edges of heat seal wheels rotating on a parallel axis but in opposite directions. There is usually a cut off knife located after the seal to cut each candy bar of the filmstrip where upon it either falls into a collection bin or onto a boxing, or cartooning line. The machine you see above is made by FMC Corp. This is a very popular brand of Horizontal Form Fill Seal Machine. As you can see I had to clean up the electrics for the heat-sealing system.