|

|

|

|

|

|

|

|

|

|

|

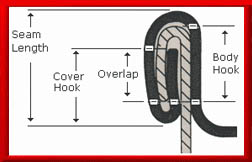

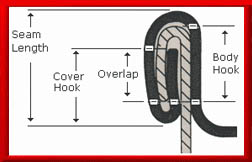

The can is another type of rigid packaging that has been around for as long as I can remember. One of the early can types that revolutionized the food packaging industry was coated tin can. This can was made from three sections. The main section was made from a roll of coated tin sheet material rolled up into a tube and seam welded. The bottom was a circular disk of coated tin and so was the top. They were both joined to the can by the process of seam sealing. Most cans are sold to product packagers as a completely preformed cylinder with the bottom attached. All the packer has to do is fill it with product and seal the top to the can.

One of the largest manufacturers of cans in the USA was the American Can Company. They had designed and built a seam sealing machine for their own use and for use by buyers of their cans. It was called the Canco can seaming machine.

This machine used a single main motor along with a series of cams and gearboxes to infeed the cans apply the top, roll a seam seal on the edge using circular dies and then feed the sealed can back onto the packaging line for labeling, casing, etc.

These machines date back to the 1950s and their mostly mechanical design required a lot of operator attention to make sure everything was correct during a run. An operator had to watch to make sure cans were on the line coming in, that the cans were full of product, that there were enough lids on the stack, stop the machine if there was jam, etc. To one machine I added a proximity sensor to detect when the stack of can lids was running low and shut the machine down. That can be seen in the photo above on the right.

Today the can is not used as much as it used to be for packaging purposes, but because the can is a very compact, light weight, high strength, free standing, stackable, rigid container, with well established scales of economy, it will probably always remain around in one form or another.